Water-Cooled vs. Air-Cooled Screw Chillers: Choosing the Right Cooling System

Through this blog, learn how to choose the right cooling system for your specific application, balancing performance and budget considerations.

Chillers are crucial in places like offices, factories, and data centers. They play a crucial role in maintaining optimal temperatures. Thus, ensuring operational efficiency and comfort. Screw compressors have gained popularity due to their efficiency and reliability.

When it comes to screw chillers, there are two main condenser types: water-cooled and air-cooled. This blog will compare water-cooled and air-cooled screw chiller to help you choose the best system for your needs.

Key Takeaways

- A water-cooled screw chiller uses water to remove heat from the refrigerant. It provides efficient cooling for large applications.

- Water-cooled chillers are more efficient and cost less to operate but have higher initial setup costs.

- Air-cooled screw chiller has lower upfront costs but higher operating expenses.

- Water-cooled screw chiller handles larger cooling loads and are better for big buildings and factories.

- Air-cooled screw chiller is suitable for smaller to medium-sized applications with less cooling demand.

- Consult reputed chiller manufacturers. Their expertise ensures you choose the optimal chiller type for your specific requirements.

Understanding Screw Compressor Chillers

Chillers remove heat from a process or space and reject it to the environment. A screw compressor in these chillers compresses refrigerant to improve efficiency and flexibility. Screw compressors are known for their durability and consistent performance. It makes them ideal for various applications.

Water-Cooled Screw Chillers

Water-cooled screw chiller has essential parts such as compressor, evaporator, condenser, cooling tower, and pumps. The cooling process involves the transfer of heat from the refrigerant to chilled water in the evaporator. The warm water is then pumped to a cooling tower, where it is cooled by air and water circulation.

Benefits of Water-Cooled Screw Chillers

- Higher Efficiency: Water-cooled chillers operate at lower temperatures, making them more efficient. They save energy and reduce operational costs.

- Greater Capacity: These chillers handle larger cooling loads. They are perfect for big buildings, factories, and data centers.

- Flexible Placement: You can place water-cooled chillers indoors. This flexibility helps in locations with limited outdoor space.

- Longer Lifespan: Water-cooled chillers last longer. Stable operating conditions and efficient cooling processes extend their life.

- Reduced Noise Levels: Chiller manufacturers make these chillers quieter. Cooling towers and other components are usually placed away from occupied areas, reducing noise.

- Better Performance in Hot Climates: They work well in high temperatures. The cooling process is less affected by the weather.

- Scalability: You can easily scale these systems. This makes them suitable for facilities that plan to expand.

- Improved Indoor Air Quality: Water-cooled systems do not exhaust hot air into the building. This helps maintain better indoor air quality.

- Environmentally Friendly: They use less energy, reducing the carbon footprint. Efficient water usage also makes them eco-friendly.

- Consistent Performance: They provide reliable cooling. This consistency is crucial for sensitive applications like data centers.

Potential Drawbacks

- Complexity and Cost: Requires a cooling tower and additional pumps. It increases the initial cost and complexity.

- Water Dependency: Relies on a reliable water source and proper water treatment.

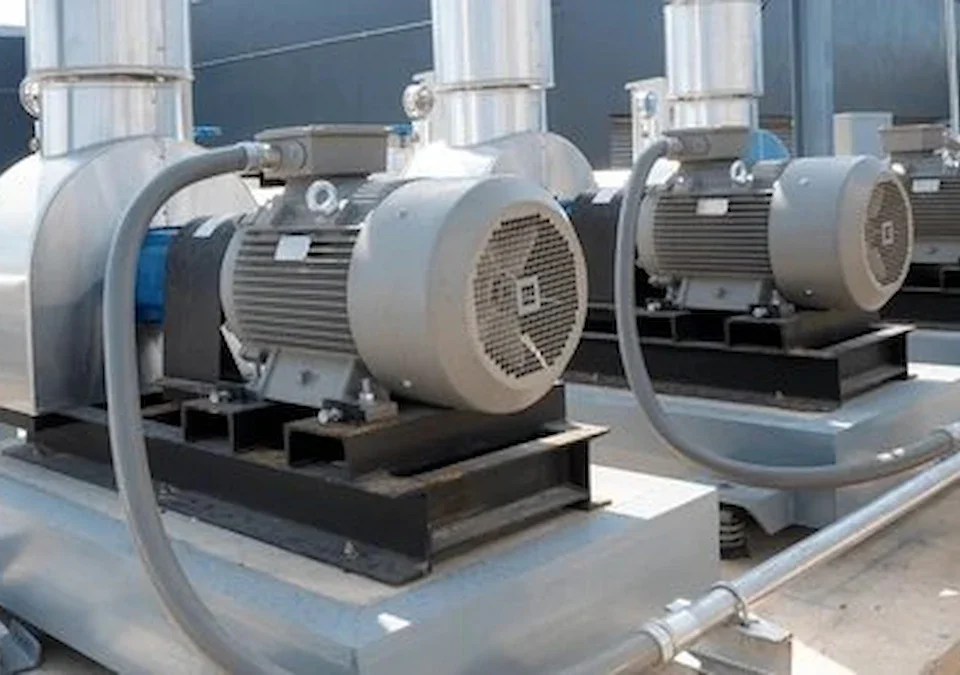

Air-Cooled Screw Chillers

Air-cooled screw chiller includes components such as a compressor, evaporator, condenser, and fan. The cooling process involves transferring heat from the refrigerant to the air through the condenser coil. It is facilitated by a large fan.

Benefits of Air-Cooled Screw Chillers

- Simpler Design: Air-cooled screw chiller has fewer components. This makes them easier to install and maintain.

- Lower Installation Cost: These chillers do not need cooling towers or extra pumps. This reduces the initial setup cost.

- Installation Flexibility: You can install air-cooled chillers outdoors. This saves indoor space for other uses.

- No Water Requirements: Air-cooled chillers do not need a water supply. This eliminates the need for water treatment and reduces operational complexity.

- Ease of Maintenance: With no water-based components, maintenance is simpler. There are fewer issues like scaling or corrosion.

- Adaptable to Various Environments: Air-cooled chillers work well in different climates. They can handle varying environmental conditions efficiently.

- Quick Setup: Installation is straightforward with fewer components. This allows for a faster setup and less downtime.

- Energy Efficiency: Modern air-cooled chillers save energy, though they are less efficient than water-cooled ones. They offer a good balance of performance and cost.

- Reliability: Air-cooled chillers provide consistent cooling. This reliability is essential for many industrial and commercial applications.

- Suitable for Smaller Spaces: They are ideal for smaller buildings and sites with limited space. They do not require additional infrastructure like cooling towers.

Potential Drawbacks

- Lower Efficiency: Higher condenser temperatures result in lower efficiency compared to water-cooled chillers.

- Limited Capacity: Not ideal for larger cooling requirements.

- Noise Concerns: Fan noise can be an issue, especially in densely populated areas.

- Performance Variability: Affected by ambient air temperature and humidity.

Choosing the Right Chiller: A Comparison Guide

| Factor | Water-Cooled Chillers | Air-Cooled Chillers |

| Initial Cost | Higher | Lower |

| Operating Cost | Lower | Higher |

| Efficiency | Higher | Lower |

| Capacity | Greater | Limited |

| Installation Complexity | More complex | Simpler |

| Maintenance Requirements | Higher | Lower |

| Space Considerations | Indoor Flexibility | Suitable for outdoor |

| Environmental Impact | Requires Water | No water usage |

Guidance for Selecting the Right Chiller

When choosing between water-cooled and air-cooled screw chillers, consider the following factors:

- Cooling Capacity: Determine the cooling capacity required for your application. A water-cooled screw chiller is generally more suitable for larger cooling needs. But, an air-cooled screw chiller is better for smaller to medium applications.

- Installation Space: Evaluate the available space for installation. Water-cooled chillers require indoor placement with sufficient space for cooling towers and pumps. On the other hand, air-cooled chillers can be installed outdoors, saving indoor space.

- Budget: Assess your budget with industrial chiller manufacturers. Also, take into account both initial and operating costs. Water-cooled chillers have higher initial costs but lower operating costs. But, air-cooled chillers have lower initial costs but higher operating costs.

- Environmental Considerations: Consider environmental factors such as water availability and noise concerns. Water-cooled chillers require a reliable water source and proper water treatment. Air-cooled chillers, on the other hand, can be noisy and are affected by ambient air conditions.

- Energy Efficiency: Prioritize energy efficiency to reduce long-term operational costs. Water-cooled chillers typically offer higher energy efficiency compared to air-cooled chillers.

Conclusion

Water-cooled and air-cooled screw chillers each have unique advantages and drawbacks. Water-cooled screw chillers offer higher efficiency, greater capacity, and flexible placement options. However, they come with higher initial costs and water dependency. Air-cooled chillers, on the other hand, have simpler designs, lower initial costs, and are suitable for outdoor placement. But, they offer lower efficiency and limited capacity. Considering all these factors will help you make an informed decision for your specific application. Refcon Chillers is one of the top industrial chiller manufacturers, offering reliable and efficient solutions tailored to your needs.

Refcon Chillers is a leading manufacturer specializing in cooling solutions. We provide a wide range of chillers, including water-cooled and air-cooled models. They are made for different industrial and commercial uses, emphasizing efficiency and reliability. Hence, ensuring our systems meet stringent quality standards. Our customized solutions are tailored to specific cooling needs. It is backed by extensive experience and technical expertise in the HVAC industry. With a commitment to innovation and customer satisfaction, Refcon Chillers continues to deliver advanced cooling technologies that optimize performance and minimize environmental impact.

Contact Refcon Chillers based in Mumbai, India for a consultation to discuss your chiller needs and explore the best options available. Our experts are ready to help you find the most suitable cooling solution for your application.