How Does a Chiller Work? – Types of Pharmaceutical Chillers

From antibiotics to complex cardiology medications, almost all medicines make use of chilled water during their manufacturing process. It is essential to maintain proper conditions in the storage room like temperature, humidity, and air quality. Pharmaceutical chillers are systems that manage the temperature control and proper cooling of medications in pharma chilling plants. Chillers offer precise control over the water temperature control which is essential for pharmaceutical products as per the WHO standards. These chillers have up to 15 to 1000 tons in terms of cooling power.

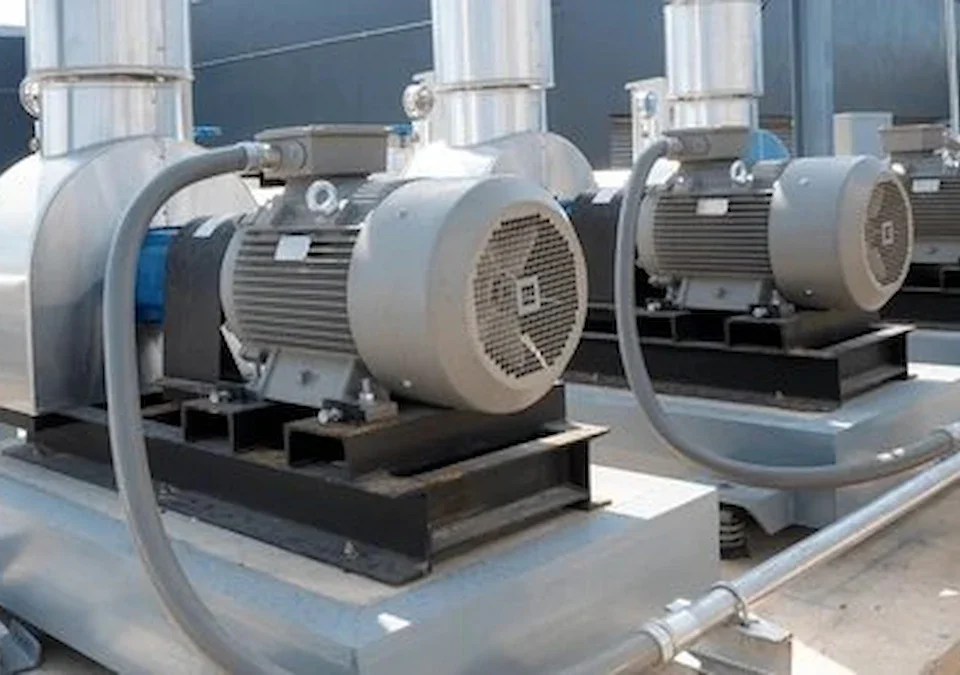

There are majorly two categories of pharmaceutical chillers Central process chillers and compact process chillers. While central process chillers can handle up to 10-200 tons of cooling power, compact process chillers are ideal for handling 1-40 tons. As the name suggests, compact process chillers occupy less space and are perfect for places where there is space restriction. There are certain standard features in every pharmaceutical chiller and they include- evaporators, pumps, tanks, cooling towers and pipes, condensers, compressors, filters, fans, and refrigerant relief valves.

In order to get your hands on the right kind of chiller for process and space cooling, it is important to know what types of chillers are there and how they work. In this blog, let us unveil the different types of pharmaceutical chillers and their mechanism.

There are four main types of pharmaceutical chillers:

- Reciprocating

The reciprocating chillers are a combination of air and water condenser, reciprocating compressor-motor assembly an expansion device along with control panel and wiring, interconnecting refrigerant piping, compressor motor-starter, auxiliaries and oil and refrigerant charge. These are the most common types of chillers as they have improved a lot over the years. They are quite compact in size and can easily fit through a 30-inch door.

Reciprocating Chillers provide many benefits. One can get them in capacities up to 200 tons. They are easy to use with the help of modern designs and controls. Since they are common, it is convenient to get technical support without trouble. There are also environmental friendly refrigerants available in the market.

- Screw Driven Chillers

Screw-driven chillers are called positive displacement devices as they compress refrigerants by reducing the refrigerant’s chamber size. These pharmaceutical chillers with screw compressors usually have capacities of less than 300 tons. The screw compressors squeeze the two rotating helical rotors there compress the refrigerant. One of the advantages of using a screw-driven chiller is that its size can be 40% smaller than the centrifugal chillers. They are also silent during operation because of the fact that they have a rotary motion and fewer moving components.

- Centrifugal

After reciprocating chillers, centrifugal chillers are the second most common type of chillers. There are more than 80,000 units of centrifugal chillers being used in North America. It removes heat from chilled waters with the help of a heat exchanger. The heat is later used to boil the refrigerant and change it into a gaseous state. A centrifugal compressor and a prime mover are the two main components of a compressor assembly. They are non-positive displacement type compressors that are responsible for changing kinetic energy into pressure to increase the refrigerant’s temperature.

The condenser also functions as a heat exchanger to take the heat away from the refrigerator. The condenser changes the refrigerant into liquid form. The heat is transferred into condenser water and then into a cooling tower. The refrigerant passes through an expansion device once it is turned into liquid form.

- Absorption

There is a heat source present in the absorption chillers to provide them with energy to cool water. These chillers make use of water as the refrigerant and lithium bromide plays the role of an absorbent. The absorption process is a thermochemical procedure instead of a mechanical one. This process occurs inside a vacuum which permits water to boil at a lower temperature. The heat source is connected to the natural gas or some other indirect source of waste heat, steam or hot water. Absorption chillers are more efficient than single-effect absorption chillers. As the double effect absorption chillers recycle some of the waste produced. Absorption chillers are built to handle a volume ranging from 4.5 tons to several hundred tons of cooling.

Refcon Chillers has enriched experience in providing like installing and commissioning complete systems that establish and maintain Pharmaceutical Clean Rooms, Pharmaceutical Air Conditioning, Pharma Chilling Plants and Condensing Unit with the required quality. We carry out Design, Heat Calculation, Pharmaceutical Clean Rooms, Pharma Air-conditioning Plants, Pharma Chilling Plants and Condensing Unit with the required quality. Our highly efficient condensing units are manufactured with utmost care and are energy-saving to consume optimum power for the required capacity.