What is a Chiller System? – Know the Industrial Chiller System Working Principles

Commercial pharmaceutical chillers are very complicated units which no commercial space can do without. To understand why you need to purchase one, it’s important to know how they work.

Air and water coolers are commonly used in commercial and industrial buildings to remove excess heat. The main purpose of using chillers is to negate the thermal energy produced by both internal and external factors. For eg, manufacturing machines, computers and people generate a lot of heat. External factors include weather conditions like direct heat from the sun.

There are two types of chillers-air cooled and water cooled. Though the way they are constructed is similar, the difference lies in how they negate heat.

- AIR COOLED CHILLER

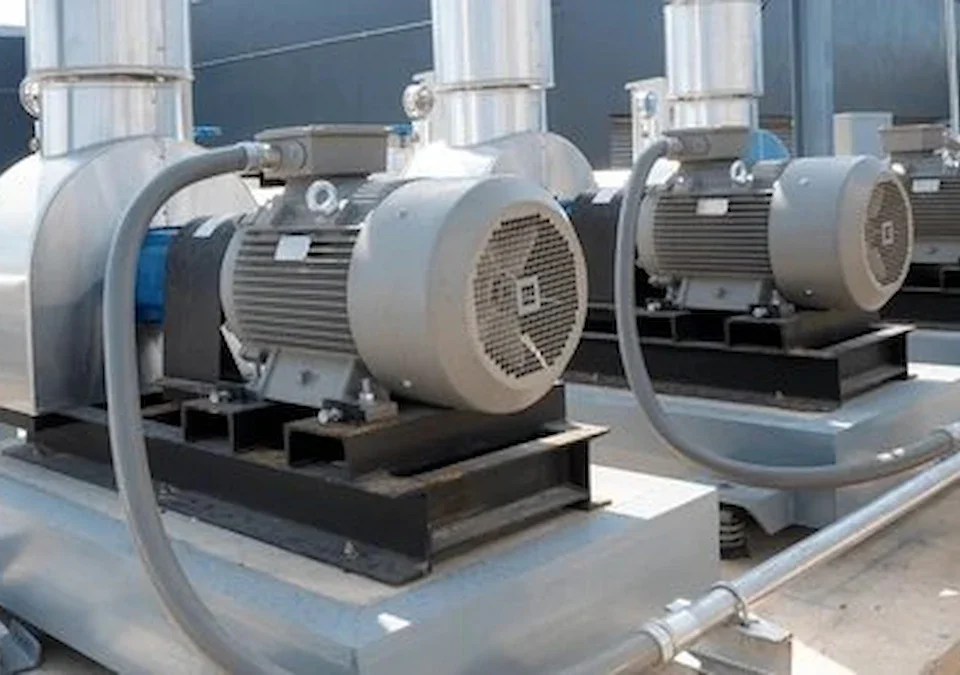

Air cooled pharmaceutical chillers are the most common types of chillers and are usually placed outside. Even though they can be installed easily and are budget friendly, they are generally less energy efficient than water-cooled chillers.

- WATER COOLED CHILLERS

Water cooled chillers are mostly used in big commercial and industrial facilities. Unlike air cooled chillers, they are placed in a custom-built plant room and are connected to a remote heat dump. The system generates chilled water and then pumps it to air dispensing units like air conditioners.

HOW DO INDUSTRIAL CHILLERS WORK?

A standard air-cooler chiller has a compressor, condenser coil, condenser fan, expansion valve and evaporator. The chiller absorbs heat from process water and redirects it into the air surrounding the chiller unit which is placed outside the facility. Most factories use this generated heat to warm up other rooms and save on money.

Process chillers contain a chemical compound known as known as a refrigerant. There are different types of refrigerants and applications depending on the temperature required but they all work on the principle of compression and phase-change of the refrigerant from a liquid to a gas to a liquid.

The chilling process in pharma chilling plants begins in the evaporator where heat is absorbed from chilled water. The compressor then extracts the refrigerant vapour from the evaporator and pumps it into the condenser. The refrigerant condenses and releases the heat into the cooling water or air. Then the liquid which was created due to condensation moves through the expansion valve which adjusts and controls the flow rate and then back to the evaporator. The liquid’s pressure and temperature get reduced along the way. As a result, the water transfers its thermal energy to the refrigerant.

Refcon has been providing turnkey services such as site erection and installation of pharmaceutical clean rooms, pharma air conditioning plants, pharma chilling plants and condenser units in India since 1999. In addition, we provide other services like design, heat calculatiostandards, thusn layout, ducting Mfg, supply of AHU condensing unit, and electrical panel. Over the years, the company has gained recognition in ASME, TEMA, ASHRAE, ISHRAE, and IS standards thus ensuring the best industrial cooling solutions and packaged chillers.